Modular Data Center Layout

1. Principle of data center micro-module

The cabinet of the data center is constructed with the minimum construction granularity of the conjoined triple cabinet, or the micro-module composed of 6 cabinets and the top-mounted air conditioner is the minimum granularity. Before the cabinet is in place, block it with a cloth curtain (or white iron sheet) to prevent the hot air from leaking out.

The conjoined triple cabinet is a cold aisle toward the outside, and a hot aisle inside the air conditioner. In this way, the hot air emitted from the server cabinets on both sides of the back-to-back gathers in the closed hot aisle between the cabinets and rises naturally, and is cooled by the air-conditioning coil at the top. After that, it is taken away by the 6 high-efficiency EC large fans on the top of the coil, and dispersed into the large environment of the entire equipment room, and then the cold air sinks naturally and returns to the cold aisle side of the cabinet to be sucked in by the server, starting the whole cycle again. During the whole process, the airflow organization is very short and efficient, there is almost no loss of cooling energy transfer, and it conforms to the natural convection law of hot air rising and cold air sinking. After the hot aisle is completely closed, the temperature difference deltaT of the air returned to the air conditioner is very high, so the required air volume of the air conditioner is small, the speed of the fan is low, and the loss can be very small, which truly achieves the purpose of efficient heat dissipation.

2. Layout of cabinet units and cooling units in the micro-module room

The cabinets are in groups of three, and the TOR at the top is placed in the middle of the triple cabinet, and every three cabinets are arranged in sequence. The two rows of cabinets are equipped with different numbers of cooling modules according to the actual power consumption of the cabinets and the type of equipment. For example, the high-load computing racks have more cooling modules than the storage racks.

If the power consumption density of the equipment in some areas is low, a small number of cooling modules can be shared by multiple triple cabinets, so that the top gap between the cooling modules can be closed by thin iron sheets to seal the hot aisle. If a triple cabinet needs to be relocated or repaired , it can be flexibly pushed away by a single operator through the bottom rollers, but after pushing away the cabinet, the iron sheet sealing plate on the front of the cooling module needs to seal the hot aisle, so as to prevent the hot air from the entire closed hot aisle from leaking into the cold environment of the equipment room middle.

3. Cooling infrastructure of micro-module data center

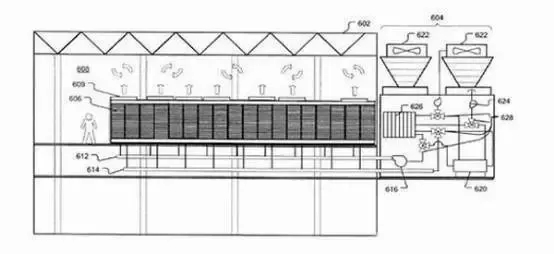

The above picture is a more detailed cross-sectional view including the cooling infrastructure of the data center. From this picture, we can clearly see that the chilled water provided by the cooling station 604 passes through the maintenance space under the floor (considering the maintenance needs of the pipeline under the floor, the actual The chilled water pipes 614 and 612 of a project of goolge with a height of up to 122cm under the floor are sent to the cooling module above the cabinet to take away the heat generated by the equipment.

The cooling station 604 includes a cooling tower 622, a plate heat exchanger 626, a cooler 620, and a water pump 624/616, etc., and adopts a design such as a three-way valve, and can choose direct cooling or indirect cooling. In actual construction, the cold station can also be a modular factory prefabricated unit, which can be transported to the machine room site and connected to the corresponding multi-row cabinet row and put into use, which truly achieves the purpose of modular and rapid construction. Redundancy between cold station modules can also be achieved by interconnecting these different cold station modules into the main ring network of the common joint, and through the interconnected ring network structure to achieve redundancy between cold stations, even if a cold station fails It will not affect the entire system.

4. The temperature of the computer room is set high to achieve energy saving

In order to save energy, the data center will set the temperature of the computer room to be higher, and the entire computer room will be used as a cold aisle. The overall temperature field is relatively uniform, and it is more suitable for operation and maintenance personnel to operate. The inlet air temperature of the server is often as high as 27 degrees Celsius or even higher. The temperature in the hot aisle is much higher, and it is not even suitable for operation and maintenance personnel to stay in it, so the servers are all designed to be maintained before the cold aisle.

For example, the temperature in the hot aisle will be as high as 43 degrees or more, the temperature after cooling by the top air conditioning coil is about 25 degrees Celsius, and the deltaT is as high as 18 degrees, so the air volume of the top air conditioner can be greatly reduced, and the fan can also run at low speed with very low power consumption. At the same time, the entire machine room operates at a high temperature of 27 degrees Celsius, the temperature of the chilled water supply can also be set at a high temperature of 20 degrees Celsius, and the return water temperature is about 40 degrees Celsius, so that the high temperature difference operation can also greatly save the power consumption of the pump. If the water supply temperature of the chilled water can reach 20 degrees Celsius, the time that the cooling host really needs to be turned on is very small every year, and even several data centers in Europe have realized the operation without a cooling machine, and the energy consumption of the cooling machine is the largest in the computer room. So these designs can greatly save energy.

5. The overall layout and construction of the micro-module computer room

The micro-module computer room is very spacious. Due to the large area, more economical and safer water fire protection is used. The top is the lighting and fire protection pipe network and rows of power supply bus bars, which directly supply power to the cabinet server through the branch wiring box. . Further down is the cable tray directly erected on the top of the cooling module, and the triple cabinet micro-module.

First build the berths for overhead air conditioners and power distribution interfaces, and use the method of triple cabinets to move the wheels, plug and play, and deliver them quickly. The machine room is also equipped with ladders, forklifts, mobile workbenches, simple maintenance workbenches, toolboxes, etc. to facilitate on-site operation and maintenance.

English

English Spanish

Spanish Russian

Russian Arabic

Arabic Français

Français