Description

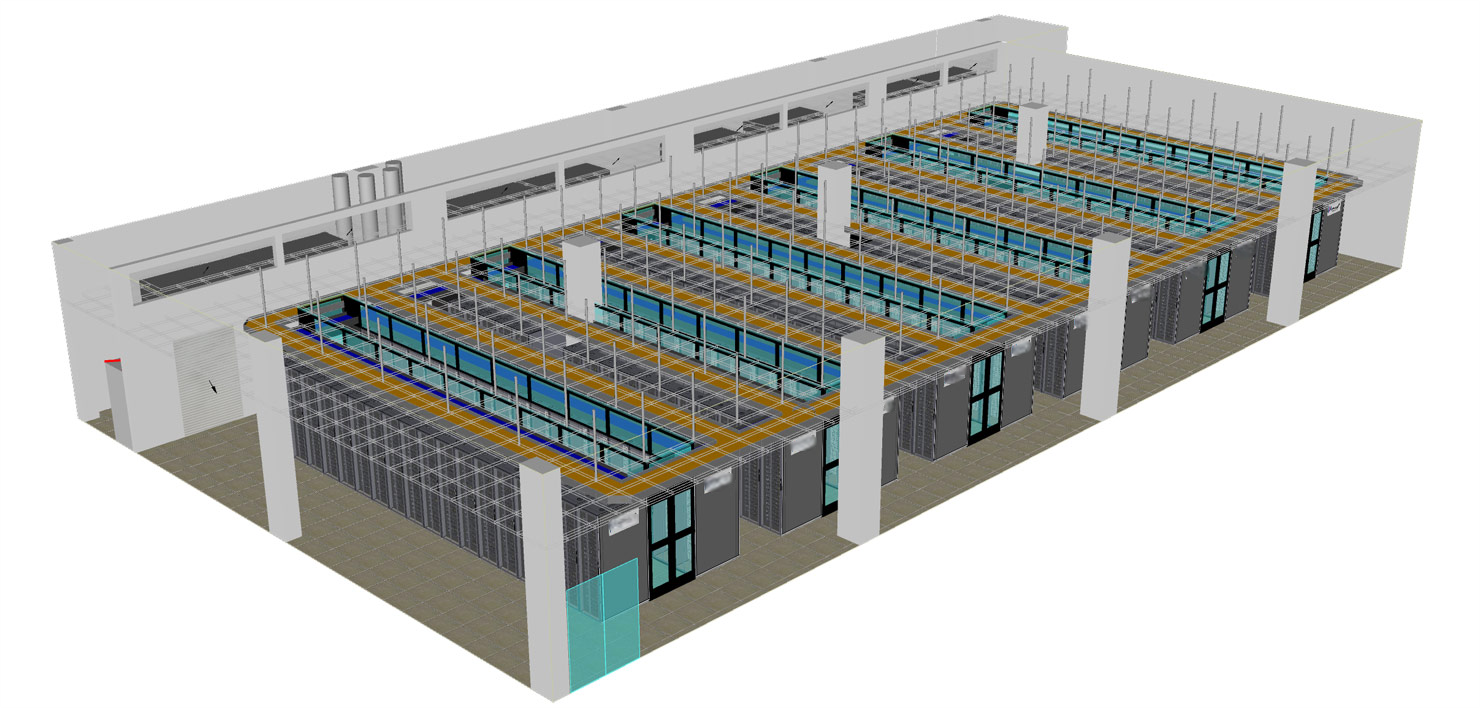

Closed Hot Aisle Containment system

Double row Hot Aisle Containment

Widely used in all kinds of new, renovated and expanded data centers in finance, government, telecommunications, energy, transportation, medical education, manufacturing and other industries

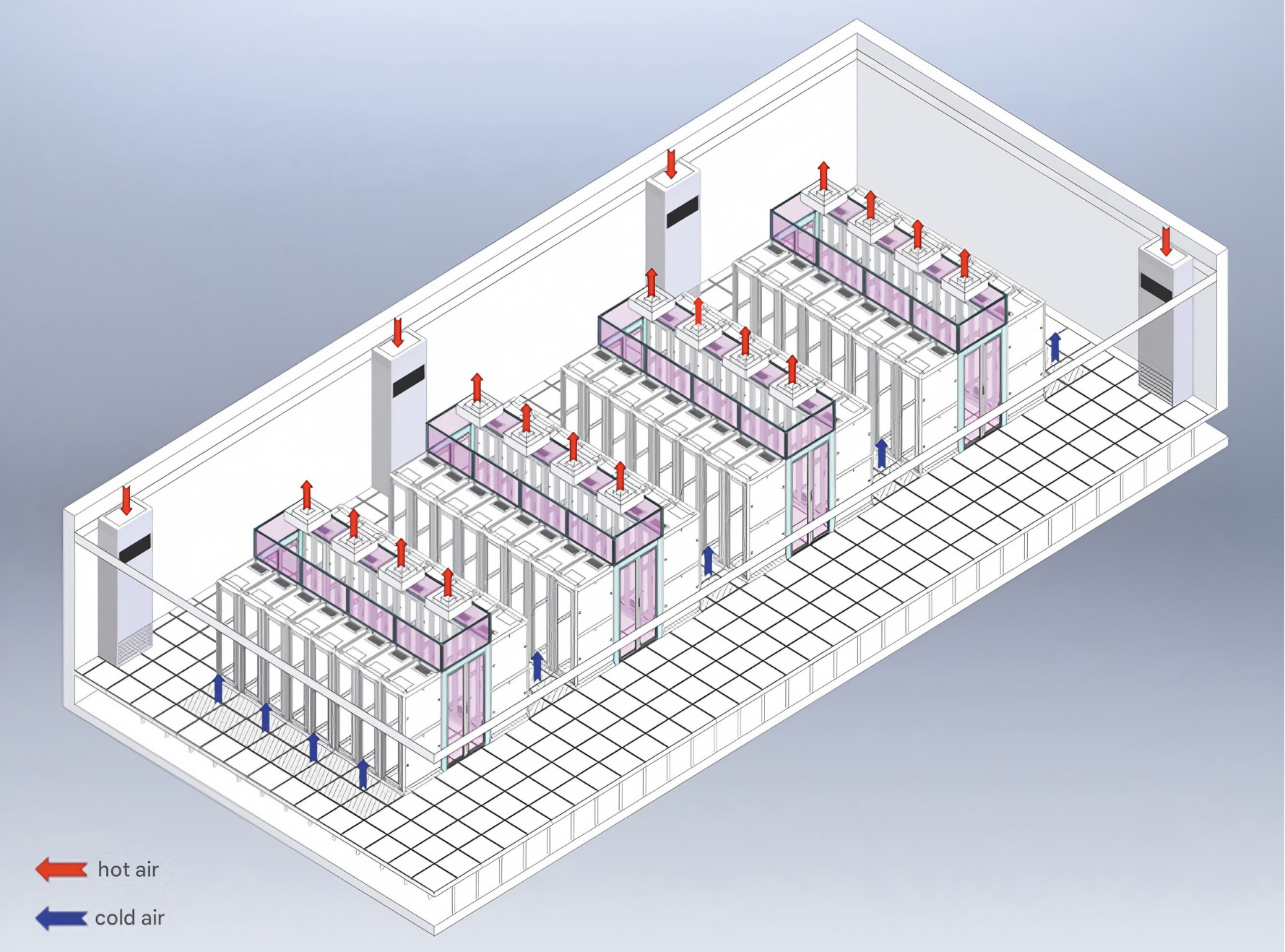

The hot channel closed system is used to control the heating environment. The hot air sent out by the horizontal air supply of the air conditioner between the rows in the channel is filled into the sealed channel, guiding the hot air to enter from the mesh door in front of the cabinet, and exhausting it from the rear door of the cabinet after cooling the equipment, forming a flowing airflow mode, which functions to prevent the mixing of hot and hot air flows, return to the return air outlet of the air conditioner in time, and improve the efficiency of hot air use, thereby achieving the purpose of energy saving and emission reduction.

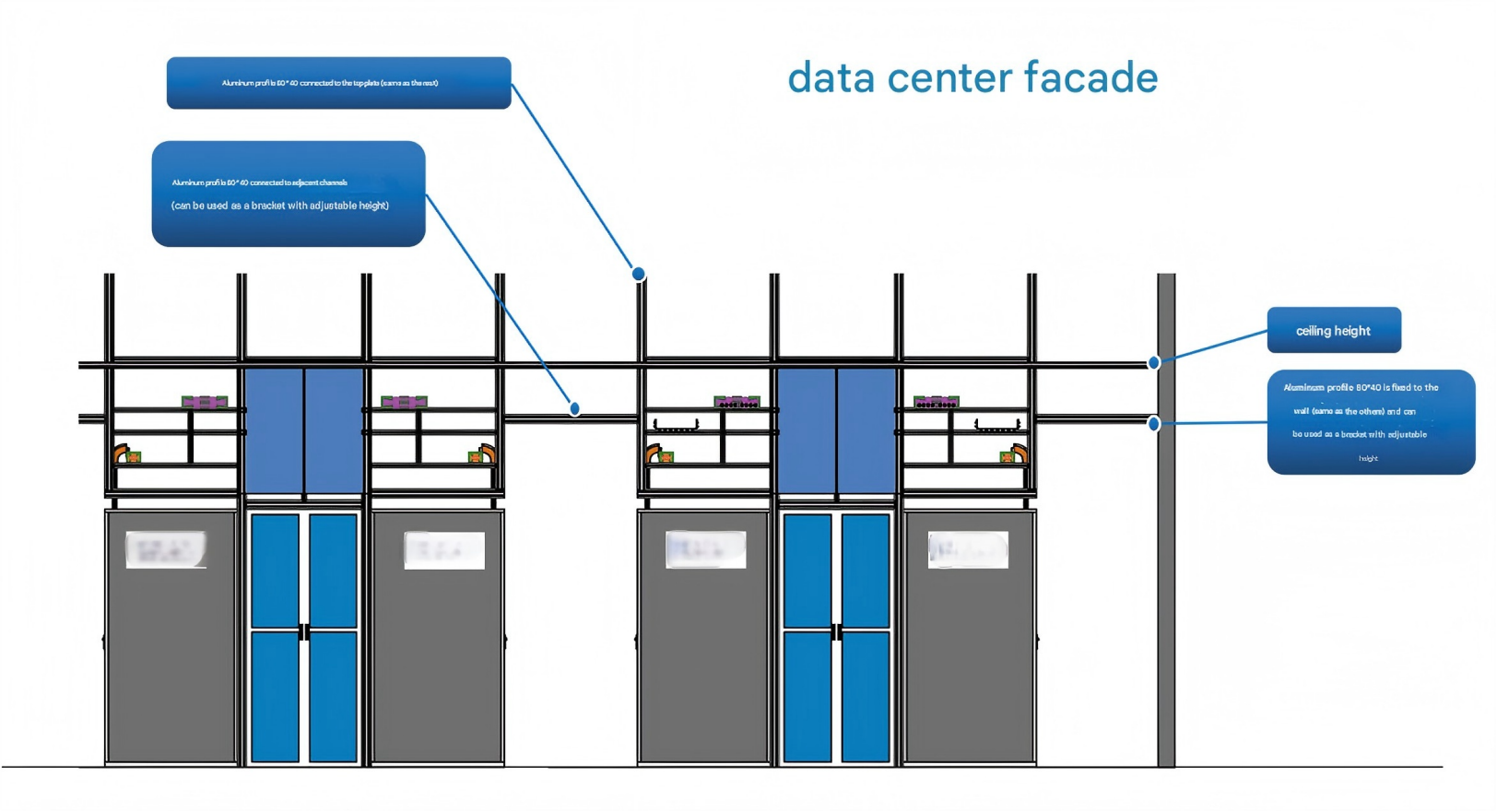

There are three designs of hot channel skylights: fixed skylights, flip skylights, and functional skylights

The skylights and observation windows use 5mm film-coated tempered glass with a light transmittance of 90%

All unit components of the hot channel adopt unique good wear resistance and corrosion resistance, fine processing, integral stamping molding, high-reliability contact, and unit components should be safe and durable without looseness to ensure the sealing of hot air flow.

The preset ports of the hot channel are linked with the fire protection of the computer room as a whole. The movable skylight is automatically opened according to different forms of fire protection signals in the computer room to eliminate the danger in the channel. The skylight supports manual, over-temperature and third-party alarm signals. The cabinet and the hot channel maintain the same appearance color. Surface treatment: degreasing, pickling, anti-rust phosphating, pure water cleaning, electrophoresis, electrostatic spraying and other treatments, no paint removal, acid and alkali resistance, solvent resistance, corrosion resistance, fingerprint resistance, and not affected by hand sweat. The surface treatment should adopt high-hardness powder electrostatic spraying and high-temperature baking paint treatment process. The surface appearance should be smooth, uniform in color, without exposed bottom, no flow accumulation, no blistering, no cracks, no orange peel, no burrs and rust on metal parts, and anti-static.

Height can be customized according to customer requirements

Single-compartment, double-compartment, and multi-compartment types can be made according to customer requirements

When connecting cabinets, cabinet combination components need to be selected

In addition, we accept orders for bases, door positioner kits, grounding terminals and other components

We also accept reverse installation of the door (left opening), please order separately

Product standards

This product complies with ANST/EA RS-310-D, IEC297-2, DIN41491, DIN41494;

PART1, PART7, GB/3047, 2-92 standards;

Compatible with 19-inch international standards, metric standards and ETSI standards.

Product color

Surface protection treatment

Degreasing, pickling, anti-rust phosphating, pure water cleaning, electrostatic spraying

Product features

2.5mm thick profile frame, industrial wide-angle open design; reliable door lock design, with multiple patents

Abundant accessories

Compact modular design, flexible configuration, saving materials

Good product scalability, such as EMC cabinets, earthquake-resistant cabinets, computer workstations, circuit breaker safety cabinets, network server cabinets, etc.

IP55 & ULType12 dual protection

CE certification

Product materials

Made of high-quality cold-rolled steel and galvanized steel

English

English Spanish

Spanish Russian

Russian Arabic

Arabic Français

Français